What Is Traditional Chrome Plating?

Chrome plating is a legacy electroplating process that deposits a thin layer of chromium over a base (often nickel over copper) using chemical baths and electricity.

Pros

• Iconic, deep mirror gloss

• Familiar, decades proven appearance

Cons

• Susceptible to micro cracking and corrosion if the surface is nicked

• Heavier due to copper/nickel underlayers

• Harsh chemicals; environmentally burdensome process

• Repair/refinish is often expensive and not always color consistent

• Can struggle in winter/salty climates without strict maintenance

What Is Chrome PVD?

PVD (Physical Vapor Deposition) is a vacuum coating process. The wheel is first prepped and typically receives a base layer (often powder coat or specific sub layers), then a metallic film is vaporized and bonded to the surface in a low pressure chamber, followed by a protective clear.

Pros

• Excellent corrosion resistance (sealed system with clear topcoat)

• Lower mass vs. old multi layer electroplating stacks

• Tougher surface more chip and scratch resistant under normal use

• Mirror like finishes plus tinted variants (Black Chrome PVD, Smoke, Brushed Chrome PVD, etc.)

• Easier care; responds well to pH neutral wheel soaps

• More eco friendly (no hexavalent chromium baths)

Considerations

• Up front cost can be similar or slightly higher than basic chrome plating, but lifetime cost is often lower due to reduced refinishing and better durability.

Side by Side Comparison

| Feature | Chrome PVD | Traditional Chrome Plating |

|---|---|---|

| Gloss / Mirror Depth | ★★★★☆ to ★★★★★ | ★★★★★ |

| Corrosion Resistance | ★★★★★ | ★★☆☆☆ to ★★★☆☆ (climate dependent) |

| Chip / Impact Resistance | ★★★★☆ | ★★☆☆☆ |

| Weight (relative) | Lighter | Heavier (multi layer metal stack) |

| Winter / Road Salt Tolerance | High with simple maintenance | Moderate; vulnerable if micro cracked |

| Maintenance | Simple (pH neutral soap, soft media) | Strict; micro cracks can propagate |

| Finish Variants (tints) | Many (Black/Smoke/Gold PVD, etc.) | Limited |

| Environmental Footprint | Lower (no hex Cr baths) | Higher |

| Refinish Path | Straightforward; consistent matching | Can be costly; color match varies |

Bottom line: For daily drivers, builds, and show and go cars, PVD delivers the look with fewer headaches.

Real World Benefits on Wheel Brands

Modern Muscle Wheels (MMW)

Why PVD: Maintains lightness and rigidity expected by late model Mustang, Camaro, Challenger owners while delivering true mirror pop.

Popular look: Black Chrome PVD on split spoke designs (e.g., M Series) accentuates concavity and brake package visibility.

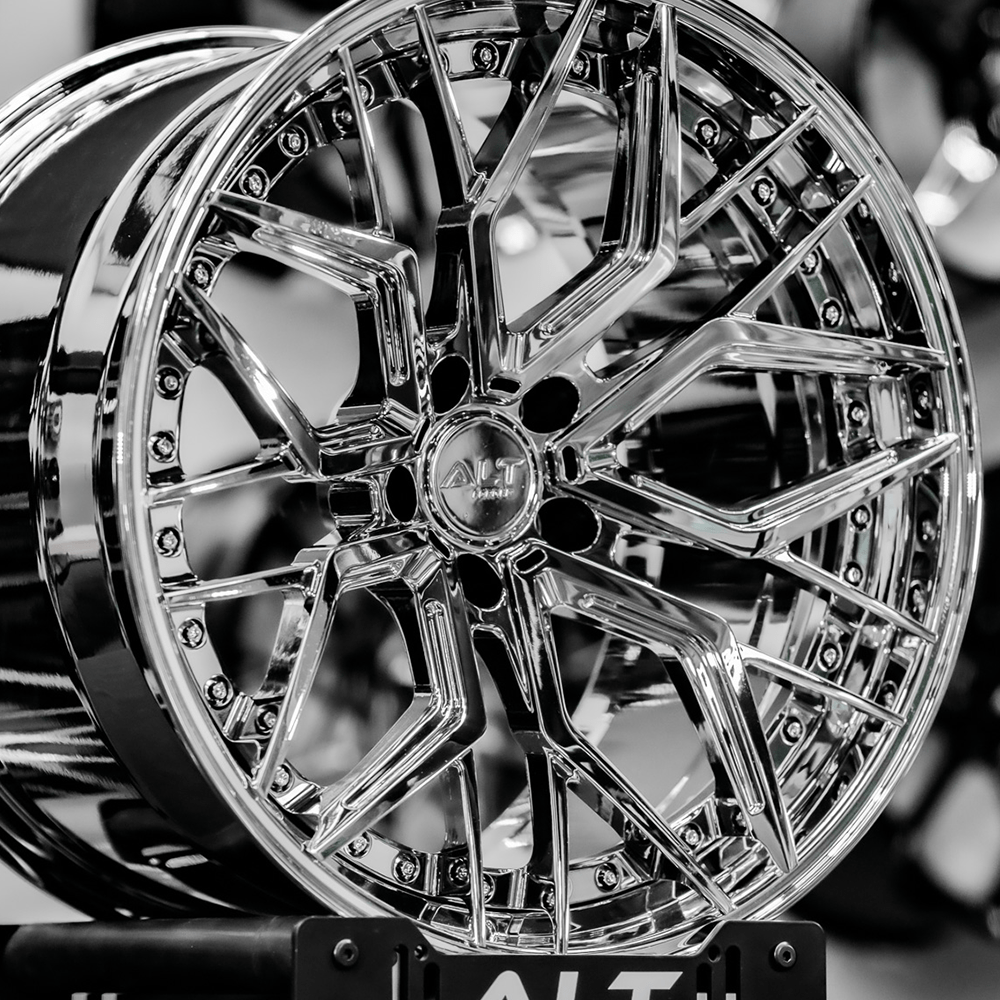

ALT Forged

Why PVD: Many ALT Forged profiles feature intricate surfacing; PVD’s thin, uniform film preserves sharp chamfers and machining details that thick plating can blur.

Builder perk: Easier finish matching across staggered or replacement singles.

Gem Forged

Why PVD: Showroom grade gloss with daily driver durability for customers who want flash without constant polishing.

Winter friendly: Strong performance in salt exposed markets when paired with proper care.

WC Forged

Why PVD: Track inspired fitments leverage PVD’s reduced mass vs. older plating stacks, helping where every ounce counts.

Finish options: Clear over PVD keeps the sheen high and maintenance low.

MRR

Why PVD: Extends longevity on daily driven Euro and domestic platforms; less pitting vs. older chrome in harsh climates.

Avant Garde

Why PVD: Complex, multi piece aesthetics remain crisp; tinted PVD (smoke/black) pairs beautifully with modern body colors and ceramic brake rotor packages.

Maintenance: Keep the Shine, Skip the Stress

• Wash cadence: Every 2–3 weeks (weekly in salty winters)

• Soap: pH neutral wheel shampoo; avoid acid or highly alkaline cleaners

• Tools: Soft microfiber mitts and plush towels; no steel wool or stiff brushes

• Protection: Silica (SiO₂) spray sealant safe for clearcoats enhances hydrophobics

• Avoid: Harsh bug/tar removers on hot wheels; aggressive compounds; automated brushes

Cost of Ownership

While initial pricing can be similar to high quality plating, PVD typically reduces lifetime costs via:

• Fewer corrosion related refinishes

• Better chip resistance

• Easier cleaning = less labor/products

FAQs

Does PVD look exactly like chrome?

Yes—Chrome PVD delivers a mirror finish. You can also opt for Black Chrome PVD or Smoke PVD for a deeper, modern tone.

Will PVD peel?

When applied on properly prepared substrates and sealed with a clear, peeling is rare. As with any finish, severe curb rash can breach the surface; seek professional repair.

Is PVD safe for winter?

Yes. PVD + clear + simple maintenance performs exceptionally well in salt and slush compared to legacy chrome plating.

How do I clean PVD wheels?

Cool wheels, pH neutral soap, soft media, rinse thoroughly, dry with microfiber, apply a light SiO₂ sealant monthly.

When Traditional Chrome Plating Still Makes Sense

• Heritage restorations seeking period correct appearance

• Trophy/show builds where absolute maximum mirror depth is the single priority, and maintenance isn’t a concern

Recommended Finishes by Use Case

• Daily Driver: Chrome PVD or Black Chrome PVD (low maintenance, high durability)

• Show Car: Chrome PVD (mirror) or Traditional Chrome (heritage look)

How to Order

-

Choose your wheel: Modern Muscle Wheels, ALT Forged, Gem Forged, WC Forged, MRR, Avant Garde

-

Select finish: Chrome PVD / Black Chrome PVD / Smoke PVD / Custom tint

-

Provide fitment details: vehicle, brake package, tire size, and desired stance

-

Approve final spec and estimated lead time

Pro tip: Ask us about ceramic coating your PVD wheels for even easier clean ups.

Warranty & Care Snapshot

• Workmanship/finish: Coverage varies by brand; PVD options typically include defect guarantees when paired with proper maintenance

• Exclusions: Impact damage, curb rash, harsh chemicals, neglect

Final Word

If you love the gloss of chrome but want modern durability, lighter weight, and easier care, Chrome PVD is the smarter finish—especially across our lines from Modern Muscle Wheels to Avant Garde. It’s the look you want with the reliability you need.

Ready to spec your set? Contact us for fitment checks, pricing, and lead times.

Legal / Disclaimer

Finish capabilities and availability can vary by brand, design, and production batch. Environmental factors (salt, pH, temperature) and user maintenance affect finish longevity. Always follow the included care guide. Specifications subject to change without notice.

Finish Variation Disclaimer: Chrome PVD is a precision coating process, but minor surface variations or microscopic imperfections are completely normal and part of the nature of the finish. There is no such thing as a perfectly flawless chrome wheel in this universe. Each wheel is unique, and small differences or subtle flow patterns are not defects but part of the authentic manufacturing process.

Share:

New: Vehicle Renderings - See Your Wheels On Your Car Before You Buy

ALT12 Forged in Black Chrome PVD